The Evolution of Bat Design: From Willow to Carbon Fiber

In the world of cricket, the bat is not just a tool but a symbol of innovation and tradition. Over centuries, cricket bat design has evolved significantly, blending tradition with modern technology to enhance performance and durability. From the natural beauty of willow to the cutting-edge materials like carbon fiber, this blog explores the fascinating journey of cricket bat design evolution, highlighting key advancements and their impact on the game.

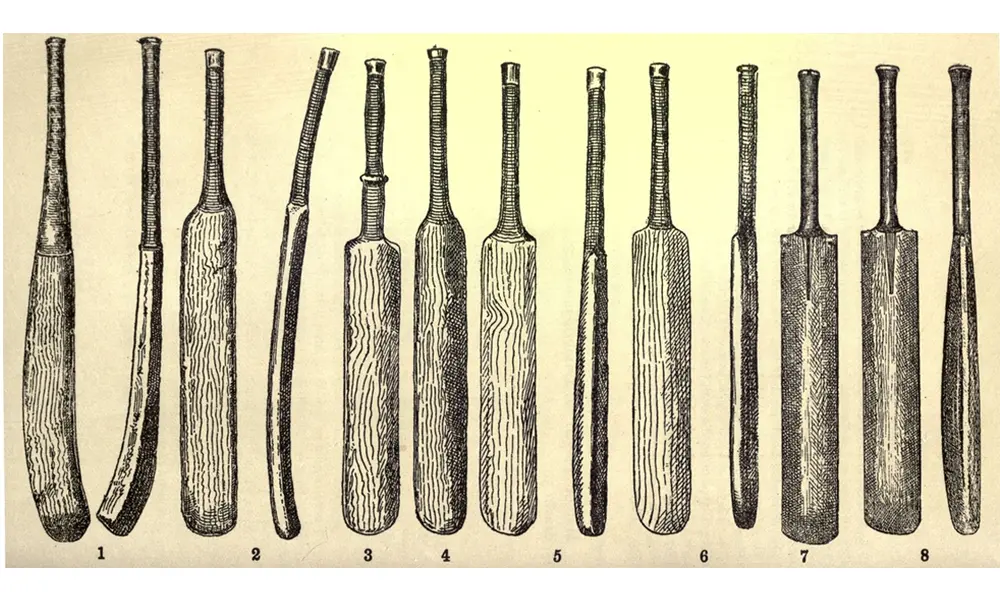

The Beginnings: Willow Wood and Tradition

Cricket bats traditionally have been crafted from English willow (Salix alba var. caerulea), prized for its natural resilience, lightweight nature, and superior shock-absorbing properties. Willow bats are known for their distinctive grains, each indicating the quality and performance potential of the bat. The evolution of willow bats has been driven by craftsmanship and a deep understanding of wood selection, ensuring batsmen could wield tools tailored to their needs on various playing surfaces.

Technological Advancements: From Traditional Willow to Modern Materials

- Fiberglass and Laminates:

- Purpose: Enhancing bat durability and resilience.

- Execution: In the mid-20th century, fiberglass and other laminates were introduced to reinforce willow bats, improving durability against wear and tear. This innovation extended bat lifespan and provided more consistent performance over time.

- Carbon Fiber Revolution:

- Purpose: Redefining bat performance and weight distribution.

- Execution: Carbon fiber, a lightweight yet incredibly strong material, revolutionized cricket bat design in the late 20th century. Its high tensile strength allowed manufacturers to design bats with larger sweet spots and reduced weight, enhancing power transfer and shot precision. Carbon fiber bats offer superior shock absorption and durability compared to traditional willow, catering to the demands of modern cricket formats.

Modern Design Features: Innovations in Bat Construction

- Bat Profiles and Shapes:

- Purpose: Optimizing bat aerodynamics and stroke execution.

- Execution: Modern bat designs feature streamlined profiles and ergonomic shapes, minimizing air resistance during bat swings. Enhanced bat handling and maneuverability improve batsmen's ability to execute a diverse range of shots with precision and power.

- Handle and Grip Technologies:

- Purpose: Enhancing comfort, control, and vibration dampening.

- Execution: Advanced handle and grip technologies incorporate materials like rubber and specialized polymers to absorb bat vibrations. Improved grip textures ensure firm bat control, reducing slippage during intense batting exchanges and maximizing batsmen's confidence at the crease.

Sustainability and Environmental Considerations

- Willow Sustainability:

- Purpose: Preserving natural resources and bat-making traditions.

- Execution: Sustainable forestry practices ensure the responsible cultivation and harvesting of willow trees for bat production. Efforts to replant and conserve willow habitats promote long-term sustainability, supporting the future availability of high-quality willow for cricket bats.

- Carbon Footprint Reduction:

- Purpose: Mitigating environmental impact in bat manufacturing.

- Execution: Manufacturers are increasingly focused on reducing the carbon footprint associated with bat production. Utilizing eco-friendly materials and sustainable manufacturing processes contribute to environmental conservation efforts while maintaining high standards of bat performance and durability.

Conclusion: Balancing Tradition with Innovation

The evolution of cricket bat design—from willow craftsmanship to carbon fiber innovation—reflects a balance between honoring tradition and embracing technological advancement. As cricket continues to evolve, batsmen benefit from bats that combine the artistry of traditional willow with the precision and performance of modern materials. Whether wielding a classic willow bat or a state-of-the-art carbon fiber model, each stroke underscores the enduring legacy of cricket bat design evolution in shaping the sport's future.